Adding confidence to efficiency metrics

Understanding the timing of each stage of preproduction, known as efficiency metrics, is imperative for having confidence in forecasting cycle times of operators and service companies. This helps ensure equipment is fully utilized and groups know what’s needed for each development phase.

To decipher efficiency metrics, it’s necessary to create a complete picture of what happens pre-production, including permits, pad construction, spud, rig release, DUC and turning-in-line first production.

Luckily, Enverus has made identifying these metrics easier than ever. Let’s take a look at three key efficiency metrics that can be identified using Enverus’ Activity Analytics within PRISM.

Conversion rates: Identify areas of growth

Conversion rate is a good key performance indicator (KPI) for permit as it helps identify areas where operators continue to invest by showing who follows through on drilling commitments. As we have seen in areas like the Delaware Basin, where regulatory environments can be in flux, operators may stock up on permits before administration changes. But those permits aren’t a true indication of planned activity. Being able to identify continued investment beyond the initial drilling permit instills confidence in which sites will be developed and where production will be coming from.

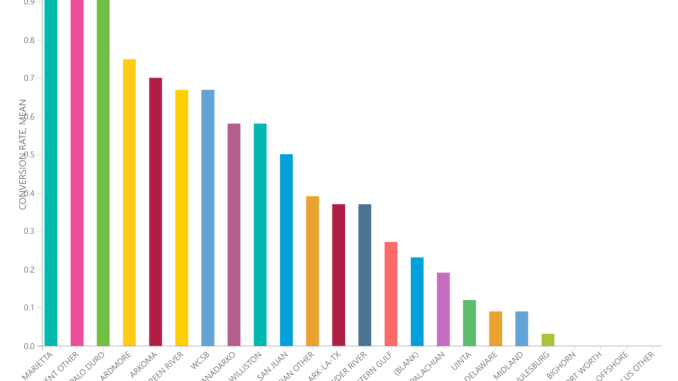

We can look at conversions, or the number of permits with detected pad construction. Evaluating conversions across basins helps decide if permits are good indicators for growth.

Permit numbers can be a quick way to gauge changes in future activity. However, some basins are far from a reliable indicator. PRISM Activity Analytics makes it easy to see this KPI change. As illustrated in Figure 1, Marietta has an ideal conversion rate of 1-1. This instills more confidence in areas with high conversion rate, compared San Juan or even parts of the Permian where permits are more speculative.

For drilling, we can add confidence to our analysis by detecting exactly when rigs move to the pad

Correlating GPS data with Activity Analytics satellite and radar data, the operators drilling the well and the contractors on site, also increases confidence in drilling analysis. This gives us a better sense of the changing market share, who’s holding steady, declining or increasing.

DUC inventory count: Indicator for future activity

As we consider outstanding investments in an area, DUC inventory is a key metric that offers insights on future activity levels. During the pandemic, we observed operators following through on drilling commitments and completing rig contracts, but not bringing frac crews on site to convert the DUCs.

For example, in Figure 2 and 3, we see Exxon maintaining their rig obligations in the Permian through the first portion of 2020, with an associated DUC build, but not bringing crews to continue work on those DUCs until much later.

With PRISM, we can see frac crews arriving on site and determine how long the DUCs have been sitting to evaluate which is closest to development. Not all DUCs are created equal, so understanding which well will be prioritized allows for more competitive service bids, better volume predictions and more accurate understanding of oilfield activity.

Downtime: Improve planning and financial modeling

Understanding the typical duration for each instance of work and the downtime between development phases enables better planning and financial modeling. With Activity Analytics, we can evaluate efficiency at every stage, including KPIs for:

Permit to spud. Instead of taking a permit at face value, users can understand how immediately applicable a permit is to an operator’s development schedule, and how likely the permit is to be acted upon.

Spud to rig release. Given that not all drilling jobs require equal work, users can anticipate how long equipment will be needed on site, allowing for more competitive bid creation and higher win rates.

Completion to first production. Ideally, all available production will be turned in line as soon as possible. However, timing may be dependent on infrastructure constraints, weather conditions or lease conditions. Understanding the turnaround time from completion to TIL allows users to understand when volumes will enter gathering systems and impact prices, and when different equipment will be necessary.

Data for Lower 48 basins indicates that the overall efficiency timeline takes from a few months to more than a year, underscoring the need to get to know your operators’ behavior. PRISM also makes it easy to apply a cluster plot to any of these well stages to get a feel for how much we can trust the numbers.

Activity Analytics provides insight into each separate phase of development, from permit to production, and enables more specific business development, transparency into proposed schedules and enhanced equipment utilization. Without PRISM, teams are reliant solely upon reported data and quarterly updates.

Click here to learn more about how Activity Analytics can help you optimize the many stages of preproduction.

The post 3 Key Efficiency Metrics for Enhanced Operations With PRISM Activity Analytics first appeared on Enverus.