Compared with conventional techniques, EKM achieves ~90% recovery efficiency, ~80% decrease in leaching agent usage, and ~70% reduction in metallic impurities in the obtained REEs.

To get to those figures, the scientists first carried out bench-scale experiments in a homemade prototype with a simulated IAD. Results suggested that the REE recovery efficiency achieved by the EKM technique was 2.6 times higher than that achieved by the commonly used ammonium leaching technique.

Then, they carried out scaled-up experiments at the kilogram scale (20 kg) in a larger EKM setup. The results were consistent with the bench-scale trials, that is, the EKM technique was able to achieve higher recovery efficiency and required less treatment time.

Based on the successful bench-scale and scaled-up experiments, the researchers applied the EKM technique to an actual IAD (~14 t-scale) during an on-site field experiment. Results suggested that the REE recovery efficiency was higher than 90% in 264 hours.

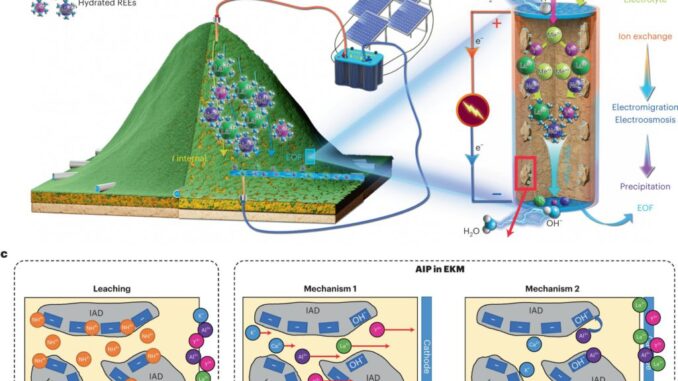

The group, thus, decided to further explore the mechanisms underlying the high REE recovery efficiency of the EKM. They noticed that the applied electric field that accelerates REEs and water migration unidirectionally towards the designed place via electromigration and electroosmosis is the key to enhancing REE recovery efficiency.

According to head researcher He Hongping, apart from its sustainability and high recovery efficiency, the EKM technique shows selectivity for REEs from other metallic impurities, namely, Al3+, Ca2+ Na+, and K+.

“We identified an autonomous impurity purification mechanism during the electrokinetic process, which is based on velocity and reactivity diversity between REE and other active metal ions,” He said.