The batteries that use the NTU-made anodes could also withstand more physical stress than their counterparts, absorbing crushing energy up to five times better.

In an article published in the journal Additive Manufacturing, the scientists explain that this new method also uses less energy-intensive processes and heavy metals compared to current industrial methods for manufacturing battery anodes. As the anode is worth 10% to 15% of the total cost of a lithium-ion battery, the technique is expected to also bring down the cost of manufacturing them.

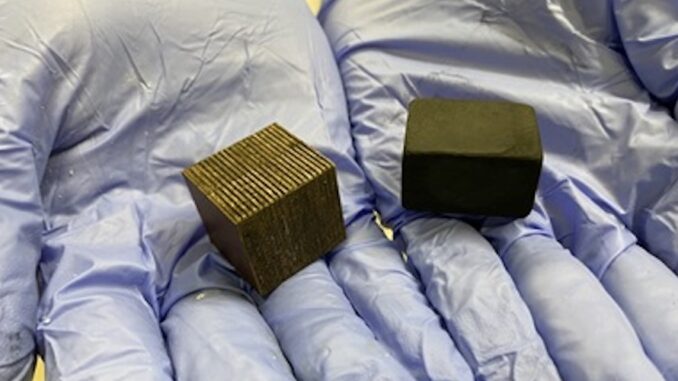

A spikey piñata

To produce the carbon anodes, the group joined and laser cut several thin sheets of kraft paper to form different lattice geometries, some resembling a spikey piñata. The paper was then heated to 1200°C in a furnace without the presence of oxygen, to convert it into carbon, forming the anodes.

The team attributes the anode’s superior durability, flexibility, and electrochemical properties to the arrangement of the paper fibres. They said that such a combination of strength and mechanical toughness would allow the batteries of phones, laptops and cars to better withstand shocks from falls and crashes. Current lithium battery technology relies on internal carbon electrodes that gradually crack and crumble after physical shocks from being dropped, which is one of the main reasons why battery life gets shorter with time. “Our method converts a common and ubiquitous material – paper – into another that is extremely durable and in high demand,” project lead Lai Changquan said in a media statement. “We hope that our anodes will serve the world’s quickly growing need for a sustainable and greener material for batteries, whose manufacturing and improper waste management have shown to have a negative impact on our environment.”

Circular economy

In addition to metal waste, paper waste is also a growing environmental problem. In Singapore, disposed paper bags cardboard, newspaper, and other paper packaging, accounted for nearly a fifth of the waste generated in 2020. Kraft paper bags, which make up the bulk of the country’s paper waste, were also found to have a large environmental footprint due to their contribution to global warming when incinerated and the eco-toxicity potential in producing them, a separate 2020 NTU study found. In the scientists’ view, their innovation presents an opportunity to upcycle waste products and reduce Singapore’s dependence on fossil fuels, accelerating the country’s transition towards a circular economy, green materials, and clean energy.