Woodfibre LNG said in a statement that this increase reflects the “evolving realities of delivering a complex, first-of-its-kind energy project in Canada—using hydroelectricity for liquefaction, net zero from day one and uniquely regulated by an Indigenous government under a consent-based environmental assessment agreement.”

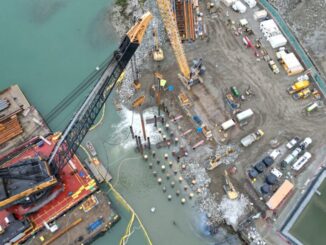

The JV noted that key cost drivers include remediation, construction, and geotechnical complexities of a “confined brownfield industrial site, including a heavily restricted marine work window.”

Are you Paying High Taxes in New Jersey, New York, or California?

Drivers also include commitment to barge-only logistics and worker marine transportation to avoid traffic impacts in Squamish, environmental monitoring, early and significant investments in electrification, including electric-drive compressors powered by hydroelectricity, and workforce accommodations located at the site, the JV said.

Despite these challenges, Woodfibre LNG is “committed to delivering” the LNG export project.

Last month, Enbridge’s management said during the company’s earnings call that the company was updating its capital investment for Woodfibre LNG.

President and CEO Gregory Ebele said that “we are never that pleased when we see more capital than we originally planned.”

“However, with Woodfibre, our contract structure does allow us to earn that double-digit return

on capital as we agreed to invest in the project,” he said.

“Fortunately, and through the agreements with departments, we’re now going to set that toll on the higher capital amount nearer to the projects in service. Our partner, which

owns 70 percent of the project, as you probably recall, they do take capital cost risk, but they get the benefit of selling the LNG commodity,” Ebele said.

“Now, with respect to capital cost increases, it’s not really one thing, right,” he said.

“We’ve had some changes in building codes. Permitting delays, not a new issue for most jurisdictions. We’re adding additional flotillas. So, that’s where we house our employees. So, that would create room for another 900 approximately folks as we get into the heavy builds and then some site condition. So, all those have really added up to this site,” Ebele said.

In a separate statement, Woodfibre LNG said that its facility passed its halfway point to project completion as four new specialized LNG modules arrived at its project site near Squamish.

Transported overseas by heavy lift vessel, the modules include two pipe rack sections, a boil-off gas compressor module, and a flare knock-out drums module.

Woodfibre LNG said the boil-off gas compressor helps with the capture of natural gas that revapourizes and its re-injection back into the process to be reliquefied into LNG.

Flare knock-out drums are designed to protect the facility’s flare system by separating any liquids from gases set to be flared, ensuring safe and efficient flare operation.

Woodfibre LNG’s construction phase is set to continue through 2025, with further module deliveries planned in the months ahead and into 2026, the JV said.

In May this year, Woodfibre LNG took delivery of the first seven modules from China at the site of its LNG export facility.

China’s Qingdao McDermott Wuchuan (QMW), a joint venture consisting of McDermott and China State Shipbuilding Corporation, built and shipped these modules.

QMW will build 19 modules, some weighing in excess of 10,000 metric tonnes, for Woodfibre LNG.

While construction on-site began in September 2023, the LNG project has adopted a modular construction approach to enhance efficiency and meet its construction timeline.

The JV plans to complete the facility, which will have a storage of about 250,000 cbm, in 2027.

Avoid Paying Taxes in 2025

Crude Oil, LNG, Jet Fuel price quote

ENB Top News

ENB

Energy Dashboard

ENB Podcast

ENB Substack