BHP has unveiled plans to replace its fleet of diesel trucks with electric trucks, in a staged transition that will not only reduce the company’s scope 1 emissions but also provide huge savings on operational costs.

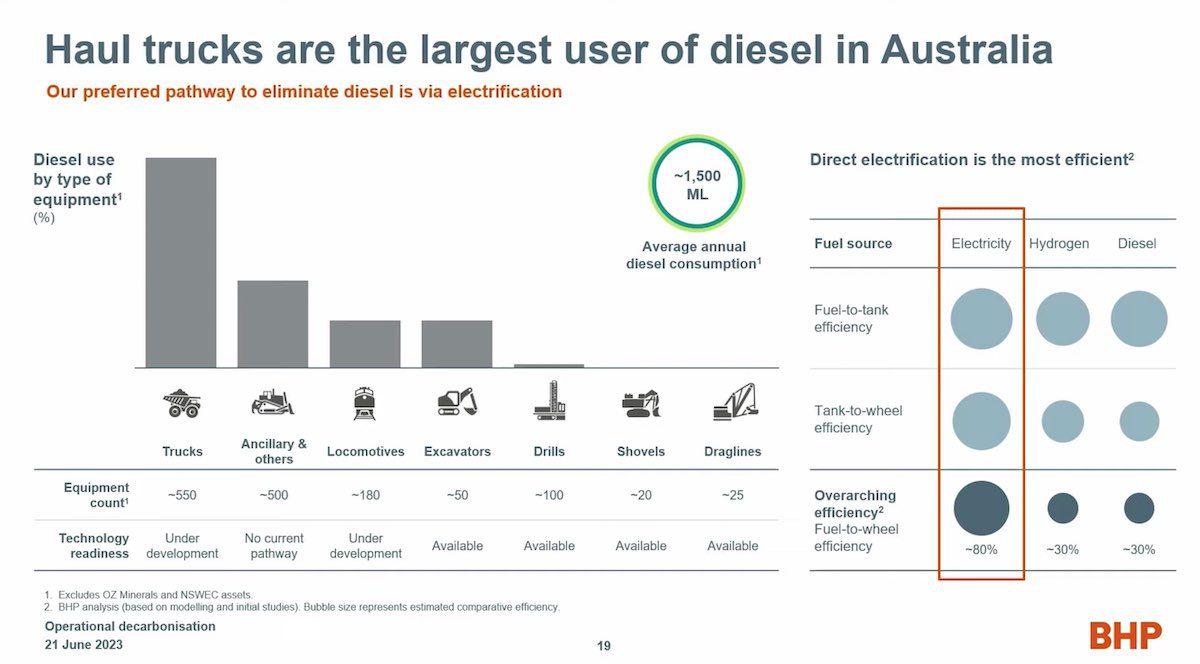

“Each year our Australian operations use roughly 1,500 mega litres of diesel in over 1,000 pieces of equipment,” said vice president of planning and technical minerals Australia Anna Wiley.

“Over half of this is used in our truck fleets. Electrification is the preferred pathway to eliminate this diesel. Part of the reason for this is energy efficiency.”

BHP says the future of big trucks is electric, not hydrogen

Wiley went on to explain the huge differences in energy efficiency between diesel, hydrogen and electric trucks (shown in the table on the right in the image below).

“The first row represents the fuel movement from source to the equipment. Using hydrogen as an example, you can see that the greatest losses at this phase are due to generation storage and transmission compared to minimal losses in electricity generation and transmission.

“Once on board, the fuel needs to be transferred into energy. In both today’s diesel electric technology and in a hydrogen system, the fuel is used to generate electricity to drive the electric wheel motors which has additional losses.

“Putting this together in the bottom row, we can see that around 80% of overall efficiency from electrified pathway compared to less than half of this for hydrogen.”

With “fuel-to-wheel” energy efficiency losses of 70% for both diesel and hydrogen compared to just 20% for electric, converting mining truck fleets to electric is a no-brainer.

But the fuel cost savings are even higher than BHP’s analysis suggests. Wiley’s comparison begins with the hydrogen fuel already created. There are also massive losses involved in creating hydrogen, according to energy expert Saul Griffith.

“It turns out the best possible case, if you have the perfect machine you’re only going to get a little more than 70% of the energy you made with your solar cell converted into hydrogen” says Griffith.

5/8

Why hydrogen is not a good idea. (Part 1)#ElectrifyEverything pic.twitter.com/C7ODUwjzPV

— Daniel Bleakley (@DanielBleakley) February 13, 2022

This means if BHP’s analysis is taken from the energy source, i.e. solar or wind power, the efficiency of the hydrogen system would drop further from 30% to just 21% with trivial losses in the all-electric system.

This means that almost 80% of the original renewable energy generated for the hydrogen system would be lost by the time it got to moving the wheels of the truck. Which means 4-5 times more wind and solar that needs to be created to travel the same distance as an electric truck and 4-5 times more cost.

Electrified mining fleet “more economical” than diesel and hydrogen

Even without the pre-fuel comparison, BHP has made up its mind on the drivetrain debate

“Our view that an electrified mining fleet is more economical and more achievable than the alternative fuel sources,” said Anna Wiley.

“Replacing diesel requires us to develop a whole operational ecosystem to surround the fleet and every part of the mine will be touched by this change.

“There are still a lot of unknowns in our future concept of operations, that we need to consider. How we plan our mines, how we charge our equipment, how we manage power demand and the skills we will need as part of this transition.

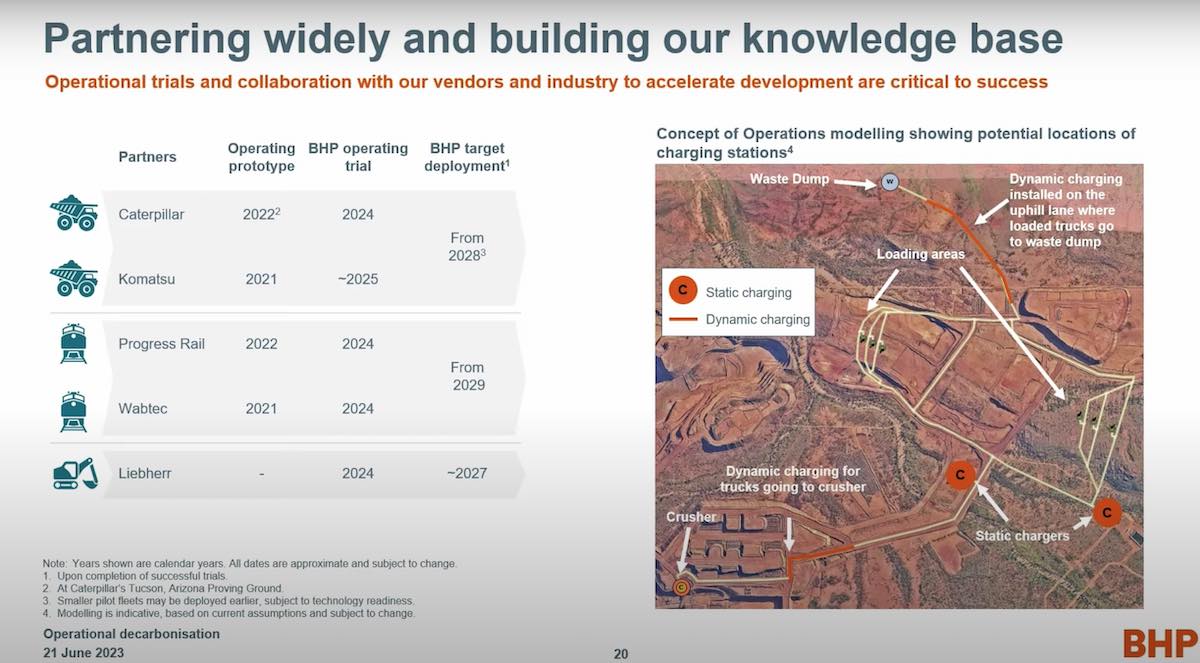

BHP says it will collaborate with equipment manufacturers to accelerate the development of electrified mine sites. BHP will trial equipment on site as it becomes available.

“I visited the Tucson proving grounds and witnessed both Caterpillar and Komatsu prototypes in operation in battery mode, which was really exciting to see.” said Wiley.

BHP says it will have its first battery electric haul truck for trialling in 2024.

“As part of this ecosystem we will need to consider how our trucks will charge. The exact design will depend on the mine itself but we anticipate having both static and dynamic charging in place.”

“For dynamic charging, conventional trolly charging is available today however implementation is difficult because as the areas we mine change, the infrastructure needs to be moved.

“We are supporting one of the Charge On Innovation Challenge participants Bluvein, who are developing side mount dynamic charging systems to improve both mobility and cost effectiveness.” said Wiley.

The Driven recently wrote a story about Bluvein, an Australian company, which has developed a

On operating costs, BHP says electric wins

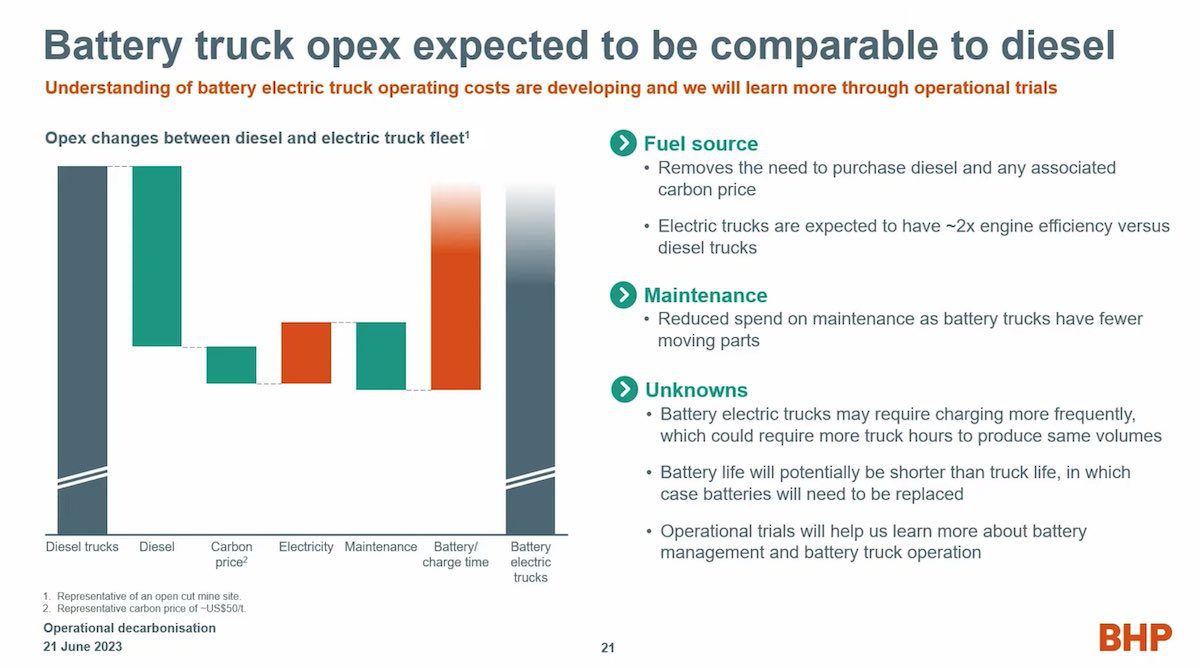

“Our initial modeling suggests the cost [of electric] will be the same or less to operate compared to diesel,” said Wiley.

“As we transition from diesel to electricity, we will spend less on carbon exposure, but we will need to spend more on electricity. However we expect the cost will be less overall given the efficiency of the battery electric trucks and the expected energy price differential.”

“We also expect to see overall savings in truck maintenance as without a diesel engine or mechanical drive chain, there are significantly fewer parts making the trucks simple to maintain.”

BHP’s modelling shows that battery charging time may be the biggest cost on the electric side, something that dynamic charging can reduce significantly.

With battery technology developing rapidly, it’s no wonder the mining industry wants to get in on the massive costs savings that come with going all-electric.