Natural gas storage — especially well-sited storage with lightning-fast deliverability rates — is taking on a new significance (and value) as LNG export facilities and power generators seek to manage their often-volatile gas demand. But developing new gas storage capacity is costly and, with only a few exceptions, it’s hard to make an economic case for greenfield projects. That reality has spurred a lot of interest among midstream companies in acquiring existing storage assets and, where feasible, expanding that storage. In today’s RBN blog, we discuss one of the biggest storage-acquisition deals to date: Williams Companies’ recent purchase of six facilities with a combined working gas capacity of 115 Bcf in Louisiana and Mississippi. (It’s not all that Williams has been up to on the gas-storage front.)

As we said in our Squeeze Box series last year, storage has long been a critically important balancing mechanism in the Lower 48 natural gas market. In the Pre-Shale Era and the early days of the Shale Revolution, the storage market was driven primarily by the intrinsic value of capacity — i.e., the need to sock away gas in the lower-demand summer months for use in the peak winter months. More recently, the value of storage is being driven almost exclusively by extrinsic economics — i.e., how flexible and responsive capacity allows market participants to manage supply and demand during short-term market swings. This flexibility and responsiveness have become more important criteria for ensuring reliability as LNG export terminals and an increasingly renewables-heavy power sector navigate frequent gas-demand fluctuations day to day — or even intraday — as well as high-stakes, extreme weather events like 2021’s Winter Storm Uri and the cold snap that gripped Texas in mid-January.

Take LNG export facilities. A number of factors can cause frequent and often-sizable swings in LNG feedgas deliveries: things like planned and unplanned pipeline or liquefaction-plant maintenance, intraday temperature fluctuations that can affect facility operations — even foggy weather that slows or stops marine traffic. As a result, operators often need to be able to call on incremental gas or inject volumes on short notice. Gas suppliers and pipelines can help manage the ups and downs, but they can’t always accommodate big swings in volumes equivalent to a large-scale liquefaction train. That’s where storage comes in.

In a similar vein, the increasing amount of variable-output renewable generating capacity that helps power the electric grid keeps the operators of gas-fired power plants on the edge of their seats — their facilities always need to be at the ready to either ramp up or ramp down their electric output to compensate for the ever-changing (and often unpredictable) output of wind farms and solar facilities. That means that generators often need reliable access to significant volumes of gas on very short notice. Again, nearby gas storage can provide a much-needed, much-welcomed assist.

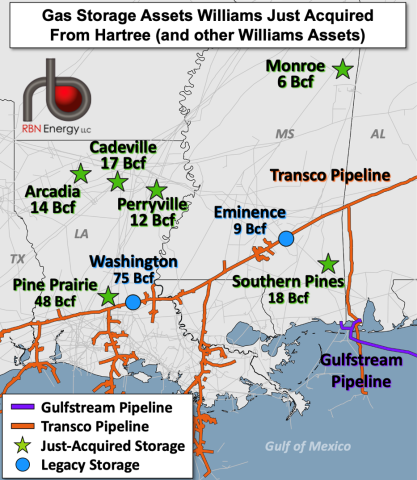

With the heightened demand for flexible, responsive gas storage top of mind, Williams earlier this month closed on the $1.95 billion acquisition of a portfolio of six underground gas storage assets in Louisiana and Mississippi from an affiliate of Hartree Partners LP. The half-dozen storage facilities (green stars in Figure 1 below) have a total capacity of 115 Bcf and — just as important, and maybe more so — a combined injection rate of 5 Bcf/d and a combined withdrawal rate of 7.9 Bcf/d. Those “deliverability” numbers are extraordinarily high and therefore are of particular value to storage customers like LNG facilities and gas-fired power plants that need to either receive or send into storage large volumes of gas at the drop of a hat.

Figure 1. Gas Storage Assets Williams Just Acquired From Hartree (and Other Williams Assets).

Source: RBN

Of the six storage facilities, four are underground salt domes (combined working gas capacity of 92 Bcf) and two are depleted natural gas reservoirs (combined working gas capacity of 23 Bcf). They include:

- The 48-Bcf Pine Prairie salt dome storage facility in Evangeline Parish, LA, which has connections to Williams’s Transco Pipeline (orange line in Figure 1) as well as ANR Pipeline, Columbia Gulf Transmission (CGT), Florida Gas Transmission (FGT), Kinder Morgan Louisiana Pipeline (KMLA), Tennessee Gas Pipeline (TGP), Texas Gas Transmission (TGT), Texas Eastern Transmission (TETCO), and three natural gas power plants.

- The 18-Bcf Southern Pines salt dome storage facility in Greene County, MS, which has connections to Transco (and, through it, Williams’s Gulfstream Pipeline to Florida; purple line), Florida Gas Transmission (FGT), Gulf South Pipeline and the Southeast Supply Header System.

- The 17-Bcf Cadeville depleted field storage facility in Ouachita Parish, LA.

- The 14-Bcf Arcadia salt dome storage facility in Bienville Parish, LA.

- The 12-Bcf Perryville salt dome storage facility in Franklin Parish, LA.

- The 6-Bcf Monroe depleted field storage facility in Monroe County, MS.

Williams noted that the Pine Prairie and Southern Pine salt dome facilities “are both well-positioned for expansions.” (See our greatest-hits blog, Smoky and the Salt Caverns, for more on how salt cavern storage space is created.) Hartree had acquired the Arcadia, Cadeville, Monroe and Perryville storage facilities from Martin Midstream Partners’ Cardinal Gas Storage subsidiary in 2019 for $212 million. Two years later, Hartree bought the Pine Prairie and Southern Pines facilities from Plains All American for $850 million.

The Williams/Hartree deal, which closed January 3, also included about 230 miles of related gas pipeline as well as 30 pipeline interconnections, a few of which we mentioned earlier. Note in Figure 1 above that in addition to the six gas storage facilities that Williams just purchased from Hartree, the company owns the 75-Bcf working gas Washington depleted field facility in south-central Louisiana and the 9-Bcf Eminence salt dome facility in south-central Mississippi (blue dots), both of which are located along Transco’s main line.

The storage facilities in Williams’s newly expanded portfolio of storage assets in Louisiana and Mississippi are either directly or indirectly linked to virtually all of the pipelines that feed the three LNG export facilities that have come online along the Louisiana coast in recent years — Sabine Pass LNG, Cameron LNG, and Calcasieu Pass LNG — as well as to the pipelines being developed to feed the new LNG export facilities now under development (see Gotta Get Over). To give a sense of the magnitude of these LNG facilities, the feedgas demand of Sabine Pass, Cameron and Calcasieu Pass averaged nearly 9 Bcf/d in December, according to RBN’s weekly LNG Voyager report.

In addition to providing support for LNG export facilities, Williams’s gas storage assets are likely to help supply the fluctuating gas needs of electric utilities in Louisiana and Mississippi, both of which depend heavily on gas-fired generating capacity and are in the midst of developing large amounts of solar capacity, which is fundamentally intermittent. According to the Solar Energy Industries Association (SEIA), about 3,000 MW of utility-scale solar capacity is expected to come online in Louisiana over the next five years and another 2,300 MW in Mississippi. A number of Louisiana utilities also rely on significant volumes of wind power, mostly from Oklahoma.

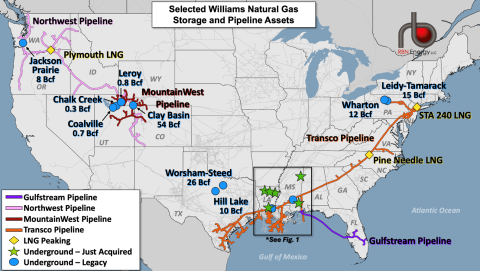

Figure 2. Selected Williams Natural Gas Storage and Pipeline Assets. Source: RBN

As shown in Figure 2 above, Williams’ gas storage assets in Louisiana and Mississippi (black box and Figure 1) are only part of a larger set of storage assets, most of which are tied to the company’s Transco, MountainWest Pipeline and Northwest Pipeline systems (orange, dark-red and pink lines in Figure 2, respectively). Along Transco, these include Williams’s 15-Bcf working gas portion of the Leidy-Tamarack and 12-Bcf working gas portion of Wharton storage facilities in north-central Pennsylvania (blue dots in that state) and two LNG peaking plants (Pine Needle and Station 240; yellow diamonds along Transco) that produce LNG that is later regasified to help meet peak-period demand for gas.

Williams has additional gas storage assets out in the Rockies and the Pacific Northwest. About a year ago, in February 2023, Williams acquired MountainWest Pipelines Holding Co. from Southwest Gas Holdings in a deal valued at $1.5 billion. In addition to the MountainWest Pipeline system — about 2,000 miles of interstate gas pipelines in Utah, Wyoming and Colorado — the MountainWest deal included 56 Bcf of gas storage. The standout among the intermountain storage assets is the 54-Bcf working gas Clay Basin depleted field gas storage facility in the northeastern corner of Utah, close to the state’s border with Wyoming and Colorado. Clay Basin, created from a depleted dry gas reservoir, is the largest gas storage facility in the Rockies. It has the capacity to inject a total of up to 350 MMcf/d from the MountainWest and Northwest pipelines and withdraw just over 700 MMcf/d around full inventory. (For context, see Blank Space on how storage ratchets work.)

In Lewis County, WA, Williams co-owns the 25-Bcf Jackson Prairie gas storage facility — the largest in the Pacific Northwest — with Puget Sound Energy and Avista Utilities; Williams’s portion of working gas is 8 Bcf. Jackson Prairie, where gas is stored in an aquifer contained by a sandstone formation, is used primarily to help the region meet its wintertime gas needs, but also to support gas-fired power plants when renewable generation ratchets up or down. The adjoining Northwest Pipeline is a 3,900-mile system that runs from the San Juan Basin in northwestern New Mexico to the Canadian border near Sumas, WA.

In addition to acquiring the Clay Basin gas storage facility as part of the MountainWest deal, Williams in August 2022 closed on the $423 million acquisition of NorTex Midstream, which owned 36 Bcf of working gas storage capacity in the Dallas-Fort Worth area — the 26-Bcf Worsham-Steed and 10-Bcf Hill Lake facilities — as well as about 80 miles of related gas pipelines. The storage facilities, which have a combined injection rate of 800 MMcf/d and a combined withdrawal rate of 850 MMcf/d, provide support to about 4,000 MW of gas-fired generation capacity in the area, as well as storage services for Permian gas directed toward Gulf Coast LNG demand. (A greenfield gas storage project planned by Trinity Gas Storage, the subject of our recent For the First Time in Forever blog, is located in the same general area.)

Williams may be among the most aggressive acquirers of gas storage in North America, but it’s not alone. For example, in two deals that closed in the spring of 2023, Enbridge purchased 77 Bcf of gas storage capacity in British Columbia — at the Aitken Creek facility near the Montney Shale — and the 35-Bcf Tres Palacios facility in Matagorda County, TX. Both storage facilities are expected to play key roles in supporting LNG export terminals in their areas. The Williams and Enbridge deals provide clear signals that interest in flexible, responsive gas storage capacity is on the rise. Expect to see more storage-related M&A in the months ahead.

“Smack Dab in the Middle” was written by Jesse Stone and appears as the first song on side one of Ry Cooder’s fifth studio album, Chicken Skin Music. The song is a jump blues tune celebrating being smack dab in the middle of the good life and partying down accordingly. It was originally recorded by its writer Jesse Stone and put out under his alias, Charlie Calhoun, in April 1955. It has also been covered by Ray Charles and The Mills Brothers. Stone’s best-known number is “Shake, Rattle and Roll,” which was a big hit for Big Joe Turner in April 1954. Stone was inducted into the Rock and Roll Hall of Fame in 2010. “Jesse Stone did more to develop the basic rock and roll sound than anybody else,” Atlantic Records President Ahmet Ertegun said. Cooder’s inclusion of the song on Chicken Skin Music is a reflection of his good taste in recording an array of often overlooked or forgotten songs that were crucial in the development of popular American music. Personnel on the record were: Ry Cooder (lead vocals, electric, slide guitars), Chris Ethridge (bass), Jim Keltner (drums), and Jimmy Adams, Terry Evans, Cliff Givens, Laurence Fishburne (backing vocals).

Chicken Skin Music was recorded during the summer of 1976 at Warner Bros. Recording Studios in North Hollywood and produced by Ry Cooder. In addition to Cooder’s unique tone and sound on stringed instruments, the album featured a mixed cast of super-talented musicians, including Milt Holland, Jim Keltner, Flaco Jimenez, Gabby Pahinui, and Pat Rizzo. Released in October 1976, the album went to #177 on the Billboard 200 Albums chart, Two singles were released from the LP.

Ry Cooder is an American musician, songwriter, film score composer, record producer, and author. He is known for his slide guitar work and collaborations with musicians from many different countries. Cooder started his professional career in 1965 when he was 17 as guitarist in the L.A. blues-rock band Rising Sons, which also included Taj Mahal. He has released 17 studio albums, four compilation albums, and 10 singles. He was the producer on the award-winning Buena Vista Social Club album, featuring traditional Cuban musicians, and recorded at Havana’s EGREM studios in 1996. The album sold over 8 million records worldwide and has been certified Platinum by the Recording Industry Association of America. He has done collaborative albums with a wide range of musicians throughout his career. Cooder continues to record and tour.